To meet the needs of rapid implementation of customer projects, ADAMUS S.A. offers high-quality format parts for blister packaging machines of all types. Our well-equipped Design Office allows us to quickly draw up design documentation to ensure the correct operation of the blister formats produced. ADAMUS S.A.’s experience also includes the design and manufacture of components for cartoning lines. This makes it possible to implement projects involving the retooling of the entire packaging process cycle.

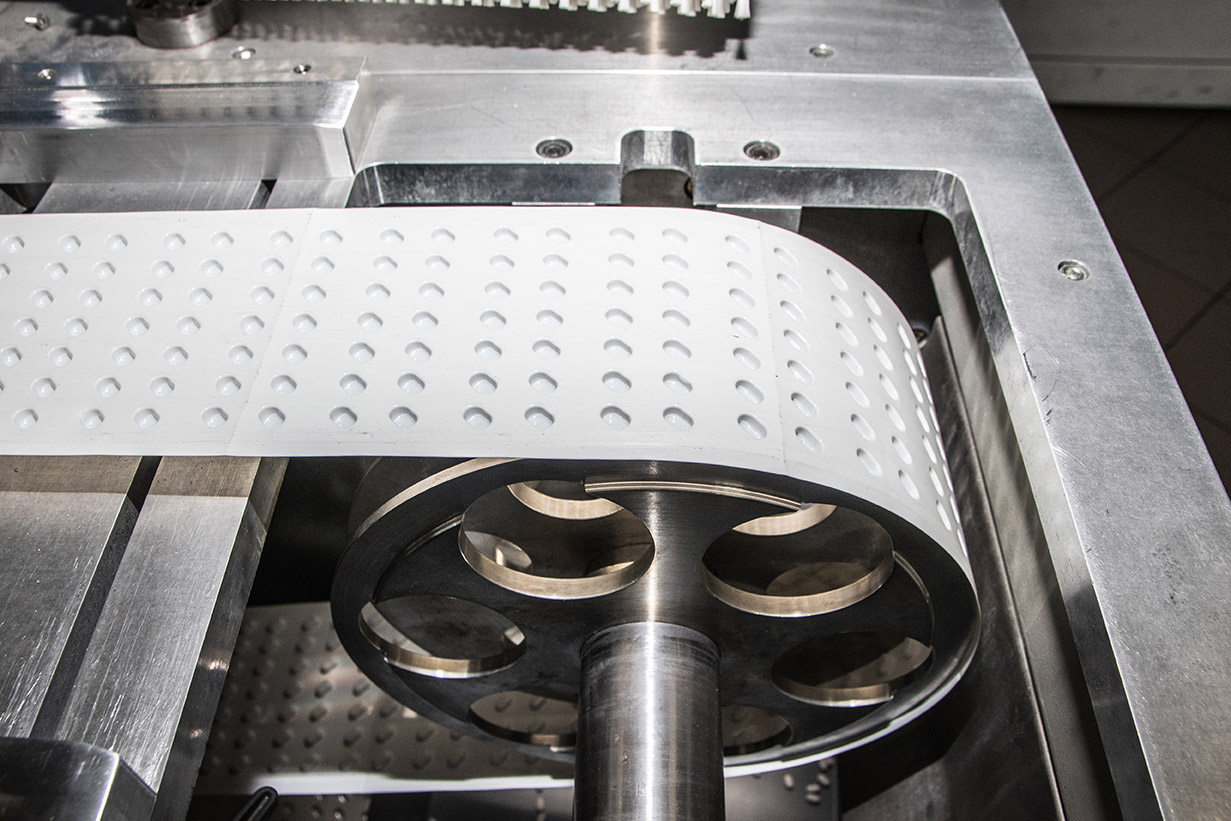

The feeding of tablets is a critical point that determines the speed and efficiency of the entire packaging cycle. Selecting and designing the right feeder plate is therefore one of the most important challenges for any supplier of blister formats.

For years, ADAMUS S.A. has specialised in the design and supply of dedicated feeder plates of various types. Our engineers work closely with customers at every stage of design, starting with determining the feasibility of feeding a particular type of tablets using a specific type of feeder plate. Immediately after the manufacturing stage, before the tools are delivered to the customer, feeder plate tests are carried out using the actual tablets and the moulded film. The process of feeding tablets at different film travel speeds is investigated on a purpose-built test bench, determining the optimum parameters for this operation. On request, our engineers are also involved in the installation and commissioning of the format, helping to troubleshoot and resolve any problems.